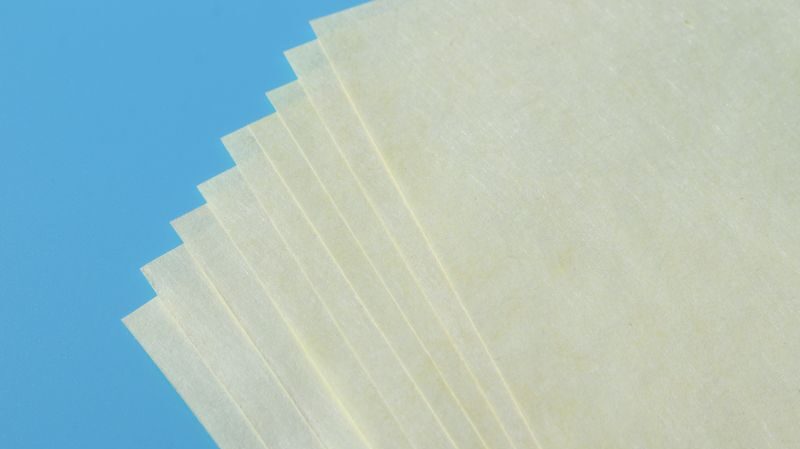

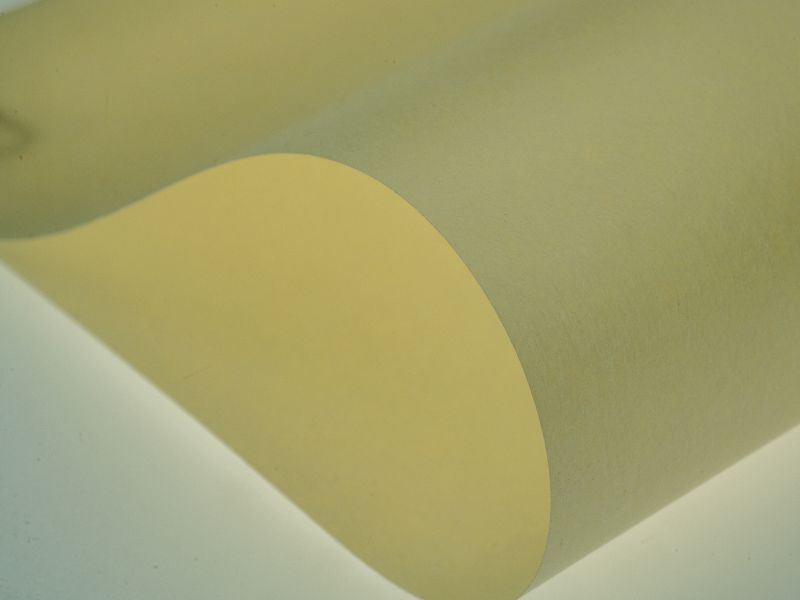

PPS Nonwoven

Overview

PPS Nonwoven is a high-performance material known for its outstanding thermal and chemical resistance. This fabric is composed of Polyphenylene Sulfide (PPS) fibers, making it ideal for applications in extreme environments. Due to its durability and resistance to degradation, PPS Nonwoven is a preferred choice in industries requiring high-quality filtration and protective materials.

Applications

PPS Nonwoven serves a broad range of industries due to its advanced properties. Its primary applications include:- Filtration Systems: Widely used in industrial filtration systems, especially in high-temperature environments.

- Automotive Industry: This material is employed in the production of heat-resistant components for automobiles.

- Electronics: Due to its excellent insulation properties, PPS Nonwoven is used in electronics manufacturing, particularly in high-voltage environments.

- Chemical Processing: Its resistance to chemical degradation makes it ideal for protective layers in chemical processing plants.

- Aerospace: In aerospace applications, PPS Nonwoven is valued for its lightweight yet durable characteristics.

Key Features

The characteristics that make PPS Nonwoven stand out include:- High Thermal Resistance: Withstand extreme temperatures without losing its structural integrity.

- Chemical Stability: It offers excellent resistance to acids, alkalis, and solvents, making it suitable for use in harsh chemical environments.

- Durability: Known for its long-lasting performance, even under continuous stress or exposure to abrasive conditions.

- Lightweight: Despite its strength, the material is light, making it easy to handle and use in various applications.

- Fire Resistance: This nonwoven fabric is naturally flame-retardant, adding an extra layer of safety in critical environments.

Technical Date

| Type | Weight | Thickness | Density | Tensile Strength(N/15mm) | Air Permeability | |

| g/m2 | μm | g/cm3 | MD | CD | cc/cm2*sec | |

| BN0020 | 17.6m | 54 | 0.3 | 41.5 | 15.9 | 201.00 |

| BN0040 | 39.1 | 108 | 0.36 | 112.4 | 32.2 | 63.5 |

| BN0060 | 63.4 | 155 | 0.41 | 205.0 | 49.2 | 31.3 |

| BN0080 | 82.8 | 172 | 0.48 | 213.0 | 112.1 | 20.30 |

| BN0100 | 100.4 | 211 | 0.48 | 285.5 | 99.0 | 15.8 |

| BN0150 | 151.2 | 295 | 0.51 | 367.0 | 163.0 | 8.50 |

| BN0010S | 10.4 | 27 | 0.39 | 19.5 | 2.6 | 293.30 |

| BN0015S | 14.4 | 35 | 0.41 | 53.0 | 8.0 | 191.00 |

| BN0020S | 20.8 | 43 | 0.48 | 82.7 | 18.2 | 92.93 |

| BN0040S | 39.4 | 57 | 0.69 | 110.6 | 41.5 | 11.03 |

| BN0060S | 64.9 | 80 | 0.81 | 259.5 | 108.4 | 4.87 |

| BN0080S | 82.0 | 111 | 0.74 | 223.0 | 126.0 | 4.12 |

| BN0100S | 108.4 | 122 | 0.89 | 291.9 | 210.7 | 1.20 |

Get in touch with our professional team!