Meta Aramid Paper / Para Aramid Paper

Aramid Paper is a special paper made from pure aramid fibers, which has high strength, low deformation, high temperature resistance, chemical corrosion resistance, radiation resistance, flame retardancy, and excellent electrical insulation properties.

It is widely used in various fields such as electric power, aerospace, rail transit, new energy vehicles, electronic communications, and other fields.

Technical Data

Aramid Paper offers excellent dielectric strength, mechanical properties, flexibility and resilience.

There are 9 thicknesses, from 2 mil to 30 mil (0.05mm to 0.76mm), it is used in almost every known electrical sheet insulation applications.

High temperature resistance can offer short-term overloading.

Electrical Properties

The electrical strength

Dielectric strength refers to the measurement of the electrical strength of a material when it acts as an insulator.

The following table reflects the instantaneous maximum electric field strength that aramid paper can withstand under 50Hz AC rapid voltage boost conditions.

|

Nominal Thickness |

mil |

2 |

3 |

5 |

7 |

10 |

12 |

15 |

20 |

30 |

|

|

mm |

0.05 |

0.08 |

0.13 |

0.18 |

0.25 |

0.3 |

0.38 |

0.51 |

0.76 |

|

Dielectric Strength |

V/mil |

406 |

406 |

508 |

533 |

635 |

560 |

580 |

533 |

482 |

|

|

kV/mm |

16 |

16 |

20 |

21 |

24 |

22 |

23 |

21 |

18 |

|

Dielectric Constant |

— |

1.5 |

1.5 |

2.1 |

2.4 |

2.5 |

2.7 |

3 |

3.1 |

3.2 |

|

Dissipation Factor |

×10-3 |

4 |

5 |

6 |

7 |

8 |

8 |

8 |

8 |

8 |

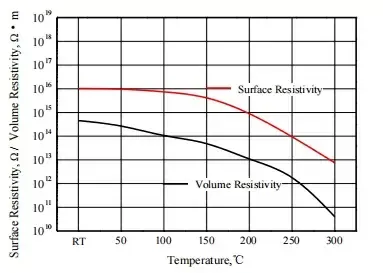

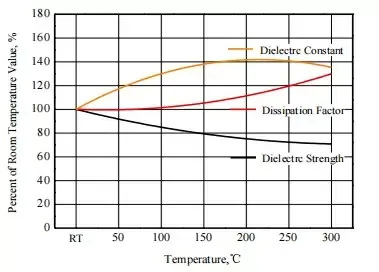

Effect of Temperature on Electrical Performance

The figure below shows the effect of temperature on the dielectric properties of aramid paper (taking 0.08mm, 3mil as an example).

It can be seen from the figure that the effect of temperature on the dielectric strength, dielectric constant, dielectric loss and resistivity of aramid paper is very low.

Effect of Humidity on Electrical Performance

As can be seen from the table, humidity (moisture) has relatively little impact on the dielectric strength, dielectric constant, dielectric loss and resistivity of aramid paper. The following table shows the effect of humidity on its dielectric properties.

|

Relative Humidity |

% |

OD |

50 |

95 |

|

Dielectric Strength |

kV/mm |

16.4 |

16.2 |

15.6 |

|

Dielectric Constant |

— |

2.1 |

2.1 |

2.1 |

|

Dissipation Factor |

×10-3 |

5.3 |

6 |

5.9 |

|

Surface Resistivity |

Ω×1013 |

1600 |

160 |

0.0025 |

|

Volume Resistivity |

Ω·m,×1013 |

11 |

36 |

0.033 |

Mechanical Properties

Aramid paper has a dense structure, smooth surface, good dimensional stability, and outstanding mechanical properties. The table below shows it’s typical mechanical property values.

|

Nominal Thickness |

mil |

2 |

3 |

5 |

7 |

10 |

12 |

15 |

20 |

30 |

Testing standard |

|

mm |

0.05 |

0.08 |

0.13 |

0.18 |

0.25 |

0.3 |

0.38 |

0.51 |

0.76 |

||

|

Typical Thickness |

mm |

0.052 |

0.078 |

0.13 |

0.18 |

0.255 |

0.29 |

0.38 |

0.515 |

0.765 |

GB/T451.3-2002 |

|

Basis Weight |

g/m2 |

41.5 |

63 |

116 |

170 |

252 |

291 |

376 |

510 |

710 |

GB/T451.2-2002 |

|

Density |

g/cc |

0.79 |

0.8 |

0.9 |

0.94 |

0.99 |

1 |

0.99 |

1 |

0.93 |

|

|

Tensile Strength N/cm |

MD |

41 |

66 |

130 |

200 |

290 |

340 |

420 |

500 |

650 |

GB/T12914-2008 |

|

CD |

17 |

29 |

60 |

75 |

120 |

155 |

250 |

345 |

450 |

||

|

Elongation% |

MD |

7.5 |

9.5 |

10.5 |

11.5 |

11.5 |

10.5 |

12 |

13 |

13 |

|

|

CD |

7 |

9.5 |

11.5 |

12.5 |

13.5 |

10.5 |

13 |

13 |

12 |

||

|

Tear Strength N |

MD |

0.65 |

1.05 |

2.2 |

3.5 |

5 |

6.5 |

10 |

13 |

N/A |

GB/T455-2002 |

|

CD |

1.1 |

2.05 |

3.8 |

4.8 |

6 |

8 |

13.5 |

16 |

N/A |

||

|

Shrinkage at 300℃ % |

MD |

3.5 |

3.5 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

IEC60819-2:2002 |

|

CD |

3 |

3 |

2.5 |

2.5 |

2.5 |

2.5 |

2.5 |

2 |

2 |

Effect of Temperature and Humidity on Mechanical Properties

The figures below reflect the effects of temperature and humidity on the mechanical properties of aramid paper respectively.

It can be seen from the figure that the influence trends of the two factors are relatively similar, the elongation shows an upward trend, and the tensile strength decreases slightly, indicating that aramid paper can maintain good mechanical strength under high, low, and high humidity conditions.

It is recommended to keep the product sealed before use to prevent the influence of moisture.

Terminal Property

Terminal property is an important property of aramid paper. it represents the work ability of long-time exposure of paper to high temperature.

Bannor aramid paper is confirmed as 210℃ insulation by UL, and also confirmed by many years’ application.

Useful life Versus Temperature of Aramid Paper:

The picture shows the relationship between the effective life of aramid paper and temperature.

Via Arrhenius aging equation it can be seen that the relative temperature index (RTI) of aramid paper is 215.4°C, and it can still maintain high mechanical strength for 18.1 hours at 400°C.

Thermal Conductivity Versus

Temperature: Thermal conductivity represents the ability of an insulating material to conduct heat and is an important thermal physical parameter of solid-phase materials.

As a key material in electrical equipment, its thermal conductivity directly determines the heat dissipation effect of the overall structure.

The picture shows the relationship between thermal conductivity and temperature.

The thermal conductivity of aramid paper is similar to that of fiber paper, and its value has a high positive correlation with the material density.

Chemical Stability

Aramid paper has excellent chemical stability and compatibility. Because its molecular structure is extremely stable, it is resistant to acid and alkali corrosion and is basically not affected by commonly used industrial solvents, as shown in the figure.

And its laminate products are fully compatible with all types of electrical varnishes, adhesives, transformer oils, lubricants and refrigerants.

The limiting oxygen index (LOI) of aramid paper is ≥28%. It does not melt in the air and does not support combustion.

The surface is carbonized to form an insulating protective layer at high temperatures. This product has obtained UL94 VTM-0 and V-0 certification.

In addition, aramid paper’s resistance to α, β, and γ ray radiation is very significant, which allows it to be used in key control equipment of high-radiation devices.