Polyimide Fiber Brief Introduction

Polyimide fiber is a non-flammable fiber in atmospheric conditions. The LOl is above 38%. It is resistant to high and low temperatures and can be used for a long time below 300℃, with a thermal decomposition temperature of more than 567℃ and no brittle breakage in liquid nitrogen at -169℃.

Polyimide fiber will carbonize without melt and drop in case of fire. The density of smoke is 1/200 of the airbus requirement. Products made of Polyimide fiber also have other excellent properties such as weather resistance,thermal insulation,chemical resistance, radiation resistance,UV resistance.

No | Item | Unit | Value | |

1 | Fineness | dtex | 0.8-6 | |

2 | Density | g/cm | 1.41 | |

3 | Breaking strength | cN/dtex | Nature clolor | >4.5 |

Dope dyeing | >3.5 | |||

4 | Modulus | cN/dtex | 36~43 | |

5 | Breaking elongation | % | 10~30 | |

6 | Suggested long-term working temp | ℃ | 260 | |

7 | Initialde composition temperature (T5%(N2)) | ℃ | 569 | |

8 | Limiting oxygen index(LOI) | % | 38 | |

9 | Acid resistance | / | good | |

10 | Radiation resistance | / | good | |

Polyimide Fiber Products

STAPLE FIBER

| Product ID | Specification | Colour |

| BN0938 | 0.9dtex*38mm | Golden yellow |

| BN0951 | 0.9dtex*51mm | Golden yellow |

| BN1638 | 1.67dtex*38mm | Golden yellow,black |

| BN1651 | 1.67dtex*51mm | Golden yellow, orange, black, dark |

| BN2238 | 2.2dtex*38mm | Golden yellow |

| BN2251 | 2.2dtex*51mm | Golden yellow |

| BN2265 | 2.2dtex*65mm | Golden yellow |

| BN2276 | 2.2dtex*76mm | Golden yellow |

| BN3351 | 3.3dtex*51mm | Golden yellow |

| BN3365 | 3.3dtex*65mm | Golden yellow |

| BN3376 | 3.3dtex*76mm | Golden yellow |

| BN6051 | 6.0dtex*51mm | Golden yellow |

| BN6062 | 6.0dtex*62mm | Golden yellow |

| BN6065 | 6.0dtex*65mm | Golden yellow |

| BN6076 | 6.0dtex*76mm | Golden yellow |

| BN1651 | 1.67dtex*51mm | Faint yellow |

| BN2251 | 2.2dtex*51mm | Faint yellow |

CHOPPED FIBER

| Product | Product ID | Specification | Colour |

| Chopped Fiber | BN0903 | 0.9dtex*3mm | Golden yellow |

| BN0912 | 0.9dtex*12mm | Golden yellow | |

| BN1606 | 1.67dtex*6mm | Golden yellow | |

| BN1612 | 1.67dtex*12mm | Golden yellow | |

| BN2202 | 2.2dtex*2mm | Golden yellow | |

| BN2203 | 2.2dtex*3mm | Golden yellow | |

| BN2206 | 2.2dtex*6mm | Golden yellow | |

| BN2250 | 2.2dtex*0.5mm | Golden yellow |

Polyimide Performance Advantages

Flame retardant performance

The limiting oxygen index

The limiting oxygen index (LOI) refers to the minimum oxygen volume fraction required to maintain complete combustion in a mixture of oxygen and nitrogen. As a new generation of high performance fiber,Polyimide fiber has better flame retardant performance than traditional special fiber, with LOl up to 38%.

| Common flame retardant fiber | Polyimide | PMIA | PPS |

| LOI (%) | >38 | 28~30 | 34 |

Low damaged length incombustion test

In vertical combustion test under Chinese fire protection criteria XF10-2014, the damaged length of Polyimide fabric is 1/5 of the aramid IIlA fabric (the mainstream FR fabric). The test result is far above the standard for protective fabric.

| Damaged length(mm) | Polyimide | Aramid IIIA fabric | 50%Polyimide 50%FR viscose | 50% amaid 50%FR viscose | Standard | |

| Flame retardant properties (25times Wash) | Warp | 10 | 46 | 12 | 60 | ≤100 |

| Weft | 8 | 48 | 13 | 57 | ||

Smoke toxicity

Polyimide fiber will carbonize without melt and drop in case of fire.

FR fabric made of Polyimide fiber passed the combustion test based on BSS7238,7239. There is ultralow smoke and non-toxic after carbonization.

The density of smoke is1/200 ofABD0031 airbus requirement. According to the smoke density test method of building materials decomposition (GBT8627-2007),the smoke density grade(SDR) of pure Polyimide felt is only 0.12, far lower than the smoke density grade of current building insulation materials.

Polyimide fiber is an wonderful material for confined space textiles, heat insulatin,home textile and protective products.

| Polyimidefabrictoxiccomparison | |||||||

| Item | Smokedensity (Dm) | Toxicgascontent (unit:ppm) | |||||

| CO | HCN | HF | HCL | SO2 | NOX | ||

| Polyimide | 1 | 32 | 0.7 | <0.5 | <1 | <0.5 | <2 |

| Airbusstandard | 200 | 3500 | 150 | 100 | 150 | 100 | 100 |

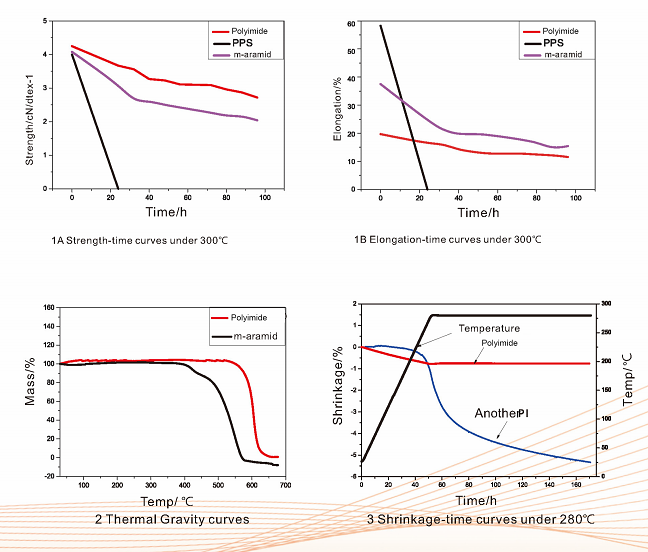

High Temperature Resistance

| The long-term service temperature of Polyimide fiber is up to 260~300℃. Initial decomposition starts from 567℃, As raw material of filter bag, the good dimensional stability and strength retention under high temperature provide higher filtration efficiency and service life. |

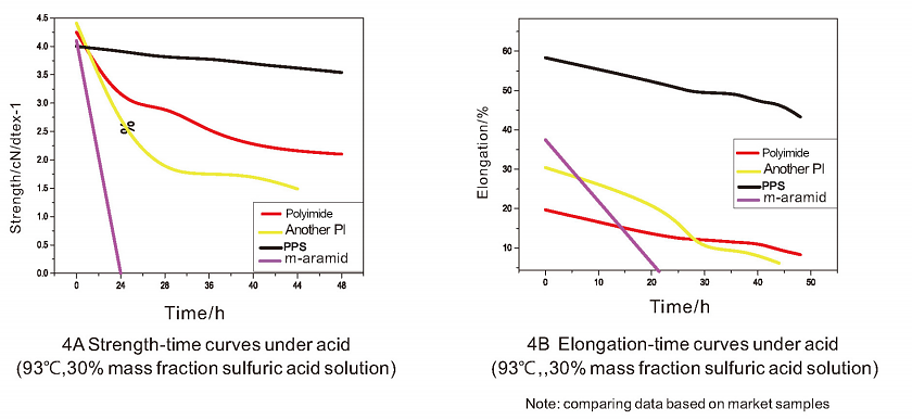

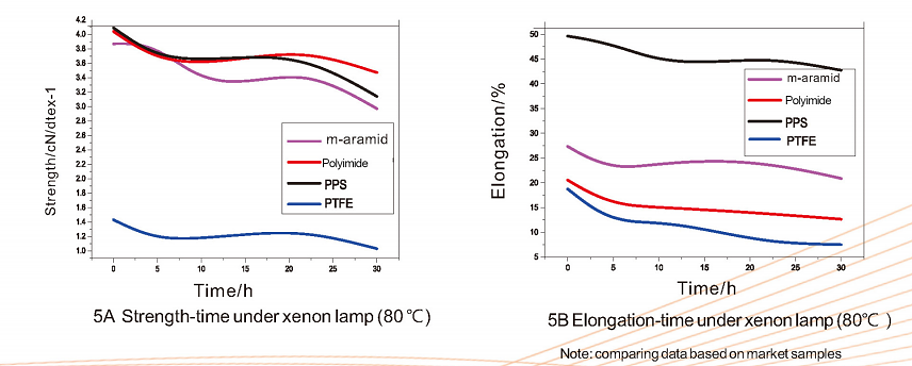

Weather Resistance and Chemical Resistance

Polyimide fiber has excellent resistance to radiation, acid, alkali and thermal oxidation. It can keep outstanding mechanical property and chemical stability in the extreme environment such as space, sea, ice and desert.

Acid resistance

Radiation resistance

Salt spray test

Using 100% polyimide yarn in accordance with GJB150A-2009 standard for neutral salt spray test.

| Item | Unit | Initial State | After testing |

| Breaking strength | CN | 21*10² | 19*10² |

| Breaking elongation | % | 16 | 15 |

Antibacterial Property

Antibacterial function

Polyimide fiber has natural antibacterial function. The antibacterial effect outperforms bamboo fiber.

| Test Item | Strain | Standard | Result |

| Rate of Antibacteria | Staphylococcus Aureus | ≥70 | 98% |

| Colibacillus | ≥70 | 99% | |

| Candida albicans | ≥60 | 99% |

Fungus test

According to GJB150.10A-2009 laboratory environmental test method of fungus test showed that the Polyimide fabric without fungus growth.

| Item | Test conditions | Amount of growth | Rating |

| Polyimide yam | 28days, humidity>90%RH temperature 30℃ | None | 0 |

Far IR Property

Far-infrared healthcare textile can promote blood circulation and metabolism,enhance immunity.

Polyimide fabrics meet the national standard for the far-infrared healthcare product with a far infrared ray of 4~16μm and normal emittance of 88%.

| Number | Test Item | Standard | Result |

| 1 | Normal emission | ≥0.80 | 0.88 |

| 2 | Wavelength | 4~16 | 4~16 |

Thermal Insulation Property

As an effcient thermal insulation material, Polyimide fiber has a very low heat conductivity coefficient, and its thermal performance is higher than that of cotton, wool, silk and other traditional materials.

The 210g/m’Polyimidefiber thermal insulation has a CLO value of 4.13 and a thermal resistance of0.64 m’·k/w, which is higher than that of 3M’s Thinsulate™ with the same weight. It has been used in cold-proof clothing and quilts.

| Category | Weight(g/m) | Thickness(mm) | CLO | Thermal resistance (m*.k/w) |

| Polyimide | 210 | 15.5 | 4.13 | 0.64 |

| Thinsulate™G200 | 200 | 20 | 3.3 | 0.51 |

| Thinsulate™ KL200 | 200 | 27 | 4 | 0.62 |

| Thinsulate™KL250 | 250 | 33 | 4.6 | 0.71 |

| Thinsulate™HZ250 | 250 | 33 | 4.3 | 0.67 |

| Thinsulate™ KZ200 | 200 | 25 | 3.7 | / |

| Thinsulate™Z250 | 250 | 27 | 4.0 | 0.62 |

Electrical Insulation Performance

The dielectric constant of polyimide is 3.4, and the corona resistance is good(parameter from the publically reported data of polyimide materials).

Color Fastness

Polyimide solution dyed woven fabric has passed the colorfastness test and the results outperform the aramid one.

| Item | Results | Testing Method |

| Color fastness to light | Grade 7 | ISO105-B02 |

| Color fastness to dry rubbing | Grade 4~5 | ISO105-X12 |

| Color fastness to wet rubbing | Grade 4~5 | ISO105-X12 |

| Color fastness to water | Grade 4~5 | ISO105-E01 |

| Color fastness to Acid perspiration | Grade 4~5 | ISO105-E04 |

| Color fastness to alkali perspiration | Grade 4~5 | ISO105-E04 |

| Color fastness to dry cleaning | Grade 4~5 | ISO105-D01 |

| Color fastness to washing | Grade 4~5 | ISO105-C10 |

Healthy Environment Protection

Polyimide fiber is environmentally friendly from manufactur

ring to end use, and has passed Oeko-Tex® Standard 100, meeting EU textile import requiren ments.

Polyimide Fiber Application

High Performance Flame Retardant Protective Clothing

|   |

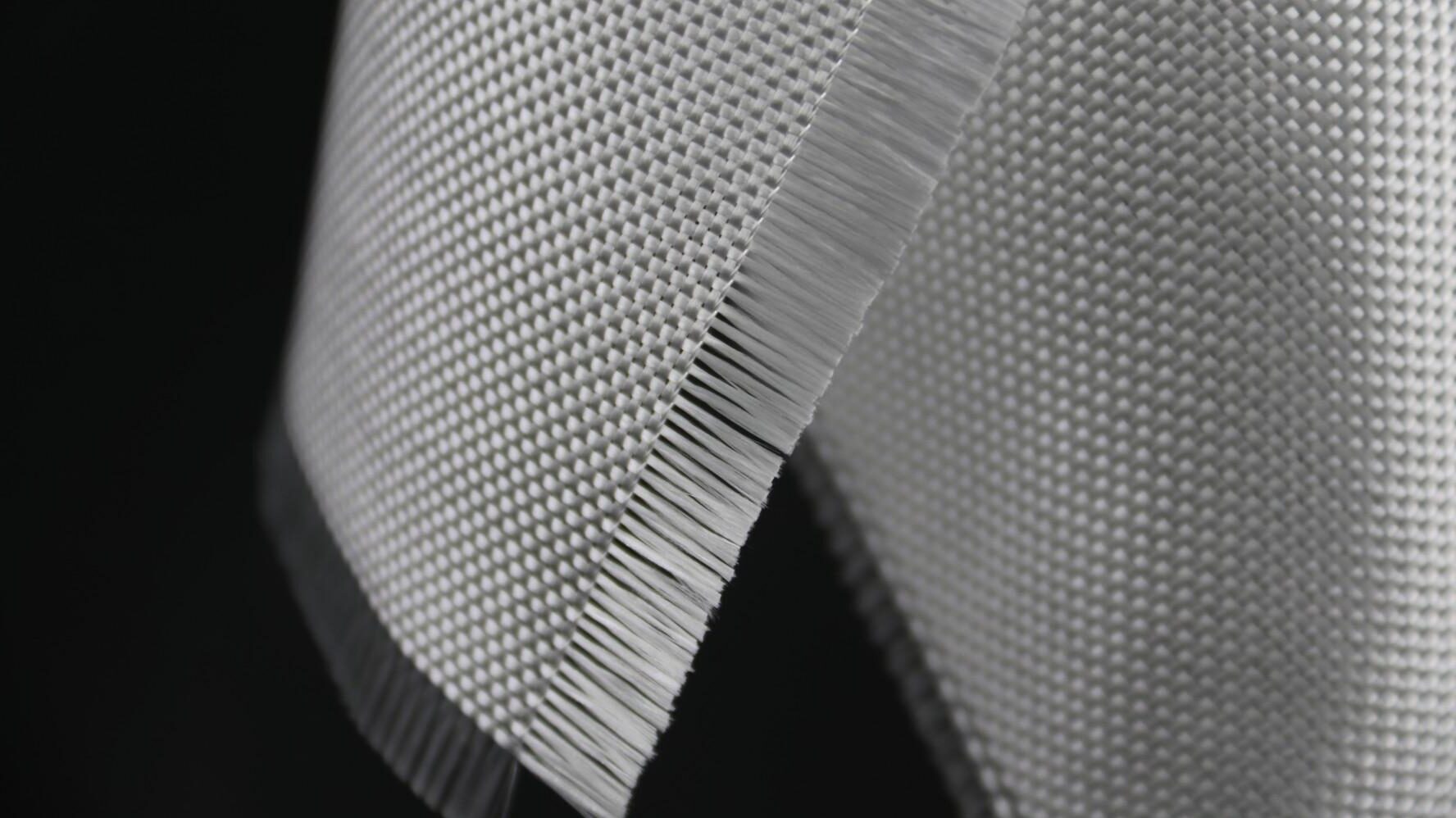

| High Performance Insulation

|

High Performance Environmental Protection Filter Material

|   |

| Composite Material

|