Aramid Fiber Products

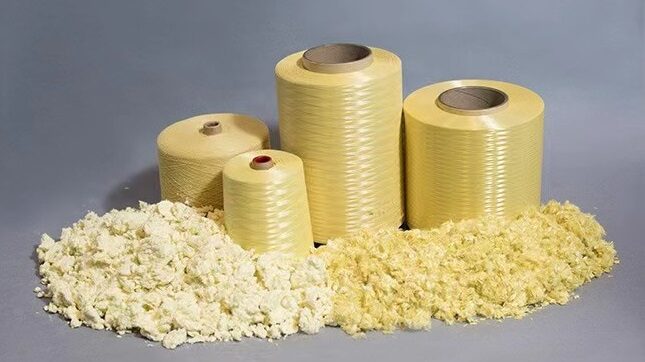

Aramid Staple

Bannor Aramid Staple staple fibers are made from filaments, which are washed, crimped and cut and then treated by surface treatment.

Staple fibers are widely used in high-end yarn, blended yarn, needle-spun felt and non-woven industry.

| Specification | DPF | Length | Crimp Percentage | Finish | Moisture Regain |

| [denier][dtex] | [mm] | [ea/inch] | [%] | [%] | |

| BN 213 | 1.5/1.67 | 38.0 | 7 | 0.35 | 7.0 |

| BN 215 | 1.5/1.67 | 51.0 | 7 | 0.35 | 7.0 |

| BN 217 | 1.5/1.67 | 76.0 | 7 | 0.35 | 7.0 |

| BN 223 | 2.3/2.50 | 38.0 | 6 | 0.35 | 7.0 |

| BN 225 | 2.3/2.50 | 51.0 | 6 | 0.35 | 7.0 |

| BN 227 | 2.3/2.50 | 76.0 | 6 | 0.35 | 7.0 |

| BNB 213 | 1.5/1.67 | 38.0 | 7 | 0.35 | 7.0 |

| BNB 215 | 1.5/1.67 | 51.0 | 7 | 0.35 | 7.0 |

Aramid Chopped Fiber

| Specification | DPF | Length | Break Strength | Finish | Moisture Regain |

| [denier][dtex] | [mm] | [ea/inch] | [%] | [%] | |

| BN 211C | 1.5/1.67 | 1 | 21 | 0 | 7.0 |

| BN 213C | 1.5/1.67 | 3 | 21 | 0 | 7.0 |

| BN 216C | 1.5/1.67 | 6 | 21 | 0 | 7.0 |

| BN 221C | 2.25/2.50 | 1 | 21 | 0 | 7.0 |

| BN 223C | 2.25/2.50 | 3 | 21 | 0 | 7.0 |

| BN 226C | 2.25/2.50 | 6 | 21 | 0 | 7.0 |

Para-Aramid Pulp

Bannor Para-aramid pulp is made from filament yarn whose composition is poly (para-phenylene terephthalamide).

After a series process of cutting, grinding and suspending in water, the fiber is fibrillated into pulp.

The pulp not only inherits the high- strength, high-modulus, high-temperature resistance, abrasion resistance and excellent chemical stability from para-aramid fiber, but also has high dispersibility, specific surface area and grip force to provide reinforcement and viscosity control under shear stress.

| Specification | C.S.F. | Specific Surface Area | Average Strength | Thermal Decomposition Temperature | Moisture Content |

| [ml] | [m²/g] | [mm] | [℃] | [%] | |

| BN 230 | 320-420 | 7-10 | 0.6-0.8 | 550 | 7.0 |

| BN 240 | 420-500 | 9-15 | 0.6-1.0 | 550 | 7.0 |

| BN 250 | 500-800 | 9-14 | 0.8-1.2 | 550 | 7.0 |

| BN 260 | 600-880 | 8-13 | 1.0-1.4 | 550 | 7.0 |

Aramid Powder

Bannor aramid powder is a high-grade, multifunctional material, primarily composed of poly(p-phenylene terephthalamide) (PPD-T).

This powder is produced through a series of sophisticated processes, including high-temperature treatment, fine milling, and special dispersion techniques.

Compared to traditional aramid pulp, the aramid powder features finer particle size and higher surface activity, demonstrating superior performance in various applications.

| Specification | Particle Size | Thermal Decomposition Temperature | Moisture Regain |

| [mm] | [℃] | [%] | |

| BN 110 | D97≤1.40 | 550 | 2.0 |

| BN 120 | D99≤0.125 | 550 | 2.0 |